Add to Cart

| Product Name: | Plastic Injection Mould | Type: | Production Mold |

|---|---|---|---|

| Cavity: | 1*2 | Core/Cavity Material: | 1.2343 |

| Surface Finishing: | High Polish | Runner System: | Cold Runner |

| Standard: | HASCO / DME / MISUMI/ LKM | Raw Material: | ABS, PP, POM, Nylon, HDPE, PVC, HIPS, TPE, TPV, TRR PMMA |

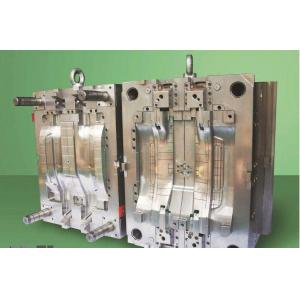

Car Parts Mold 2 Cavities Plastic Injection Mold Built In HASCO Standard With Inserted Blocks

This 2 impression fully hardened mould has gone through the factory very smoothly because we’ve worked closely with the customer and have an excellent understanding of what they want and why they want it. I can only hope they’re as happy with the finished product as we are.

Specifications:

| Company name | ERBIWA Mould Industrial Co., Ltd. |

| Product Name | 20 experience OEM 3D design auto car parts plastic injection tooling mold for Toyota USB car charger |

| Mold Base | SD,LKM Standard, HASCO Standard Self-made, etc. |

| Mould Material | P20/718/738/NAK80/S136/2738/2316/H13, etc. |

| Moud Precision | +/-0.01mm |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Gate type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Plastic Material | PA6,PA66, ASA, POM, PPS, ABS,ABS+GF,ABS+PC,POM(Derlin),PP, PE,PC,PMMA(Acrylic),PVC,PEI,PBT,PTFI |

| Metal Material | Aluminum (6061,6063,7075...),Brass, Copper, Brass,Satinless Steel(301,302,303,304...) |

| Surface Treatment | Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |