Add to Cart

| Product Name: | Plastic Injection Mold | Type: | Prototype / Production Mold |

|---|---|---|---|

| Cavity: | 1*1,1*2,1*4,1*8, Or As Per Your Requests | Core/Cavity Material: | 1.2343/NAK80/1.2311/SKD61,S136,P20,H13,738H ... |

| Surface Finishing: | Mirror Polishing / Polish/texture/EDM | Runner System: | Cold Runner/hot Runner (Syventive, Moldmaster, INCOE, HRS, YUDO...) |

| Standard: | HASCO/DME/LKM/MISUMI/FUTUBA | Raw Material: | ABS, PP, POM, Nylon, HDPE, PVC, HIPS, TPE, TPV, TRR Etc. |

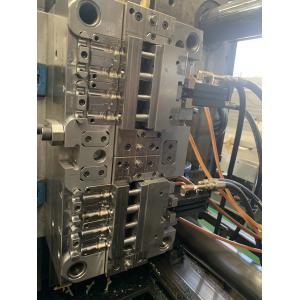

Plastic injection mold

Specifications:

| Mould information | Size | Depends on customers requirement (2D/3D) |

| Color | transparencey or according to client's requirements | |

| MOQ | 1 set | |

| MOLD LIFESPAN

| 500-1000000 shots | |

| Brand | Canon, Epson, Brother, Sony, Tyco, Audi, Honda, Toyota and Flextronics, Fuji Xerox, HP, JST, Kyocera, Panasonic, BMW, Sanyo, ZTW | |

| Mold Details | Type | Prototype mold and series/production mold |

| Standard | Hasco,DME,LKM,FUTABA,other | |

| Cavity/Core material | 1.2343/1.2311/SKD61,S136,NAK80,H13,738H,other | |

| Injection | Cold runner/hot runner(Moldmaster,YUDO,INCOE,HUSKY,MOLD-TIP,other) | |

| Cycle life | 500k~1000k shots | |

| Service | One stop service | Design- Mockup- Manufacturing- Assembly |

| Design | CAD/CAM technical platform and perfect engineering data switching system which enable us to have elastic choices to offer service to our customers. UG 4.0 DXF, DWF, PRT, SAT, IGES or STE format for mold design and layout | |

| Mockup | Rapid laser mockup /CNC mockup process | |

| Manufacturing | Prototype mold,production mold,plastic parts production | |

| QC | Latest precise detecting instruments Well trained and skillful inspectors Timely feedback to manufacturing department High yield rate and timely delivery

| |

| Delivery | SAMPLES SHIPPED BY FEDEX,DHL,TNT,UPS. Sea or air shipment for Mold/mass production |

Description

1. Forwa mould is able to offer the full range of service from mold designing, making, plastic part molding to printing, assembly, package, and shipping arrangement.

2. Engineering/ Technical

﹡ Mold design

﹡ Mold flow analysis

﹡ Project management

﹡ Supplier Managed Inventory

﹡ Design for Manufacturing

﹡ Value Analysis

3. Mold Build

﹡ Mold up to 450 tons

﹡ Complex Surfaces

﹡ Assembly Fixtures

﹡ Hot-Runner Capability

4. Technical Injection Molding

﹡ 20 to 450 Tons Injection Molding Presses

﹡ Structural Foam

﹡ Small Precision and Large Cosmetic

5 . Secondary Operations

﹡ CNC Machining

﹡ Sonic Welding

﹡ Heat Staking

﹡ Hot Stamping

﹡ Pad Printing

High yield rate plastic injection mold with 16 cavities.

16pcs plastic parts per 25 seconds which high capability can suit for customer's requirement for each month.