Add to Cart

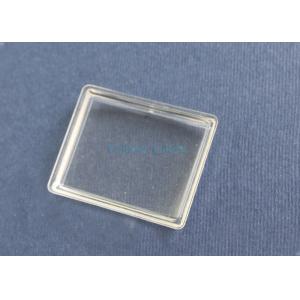

Rectangle Car LED Indoor Plastic Reading Lamp Shades & Cover With Transparency

Product description

| Product Name | Car LED Indoor Plastic Reading Lamp Shades & Cover Mould |

| Type | Injection mould |

| Standard | LKM , HASCO , DME, etc |

| Certification | ISO 9001:2015; IATF 16949:2016 |

| Mould Life | 300,000-1,000,000 shoots as required |

| Leadtime | 30-45 workdays based on the different products |

| Package | Wooden case package or as customer requirement |

| Payment Term | TT,30% deposit to arrange production,70% defore delivery |

Features

1. Several years' experience

2. CAD/CAM/CAE system

3. CNC, wire erose, EDM machine

4. Strict quality management

5. Reasonable price

Advantages of our auto car parts injection :

We have a professional tooling design team with several years experience.

1. Various materials and short lead-time

2. Good steel and long lifetime .

3. We can supply "one-stop" service with molds opening, injection, painting, screen printing, assembly and nice after-sales service in long term

4. Full set of machines for mold making and injection molding

5. OEM&ODM service available

6. Mould's design based on tooling engineer from our company and experienced with years in the dustry.

7. Mould's steel as per customers' requests such as NAK80, S1369(H),2738, 718, 738 and etc.

8. Final products' materials' optional: ABS, PP, PE, POM, PA6(66)+GF, PC, PMMA, HIPS, GPPS and etc.

9. Products' color: As the customer's requirments, any color is possible, if they could provide us the color card schedule.

10. Relevant requirements reachable: RoHS, UL, or as the request.

11. Certifications Authorized: ISO9001&ISO14001 Certificated.

12. Japanese standard of QC management and Euramerican standard of checking.

13. Service scope: Open mould, Injection, CNC processing, coating, screen printing, assembly for finished products and so on.

14. Good cost and high effeciency of delivery.

Packaging Details: auto plastic shade packing :Foam+Wooden case

Delivery Time: 30-40 days after receiving the deposit

Company Profile | Structure of Company | Private-operate |

| Worker No. | 50-100 | |

| Engineer No. | 15 | |

| Products | Stamping parts, casting parts, lathing parts, springs and other hardware materials | |

| Main market(client) | USA/Germany/Canada/Italy/United Kingdom/Australia/Pakistan/French etc | |

| Factory Scale | 3000 Square Meters | |

| Type of Company | Manufacturer | |

| Year of Foundation | 2016 |